Manufacturer of Market Milestones

EAW (Ernst Apel Würzburg), the German manufacturer of high-quality scope mounts, has done it yet again – become the world’s first. Their launch of the pivot mount system in the 1970s was a ground-breaker. Not only they pioneered the pivot mount – 50 years later, and the design has been often imitated but never duplicated by the competition. Now, the company has unrolled another milestone product with high aspirations.

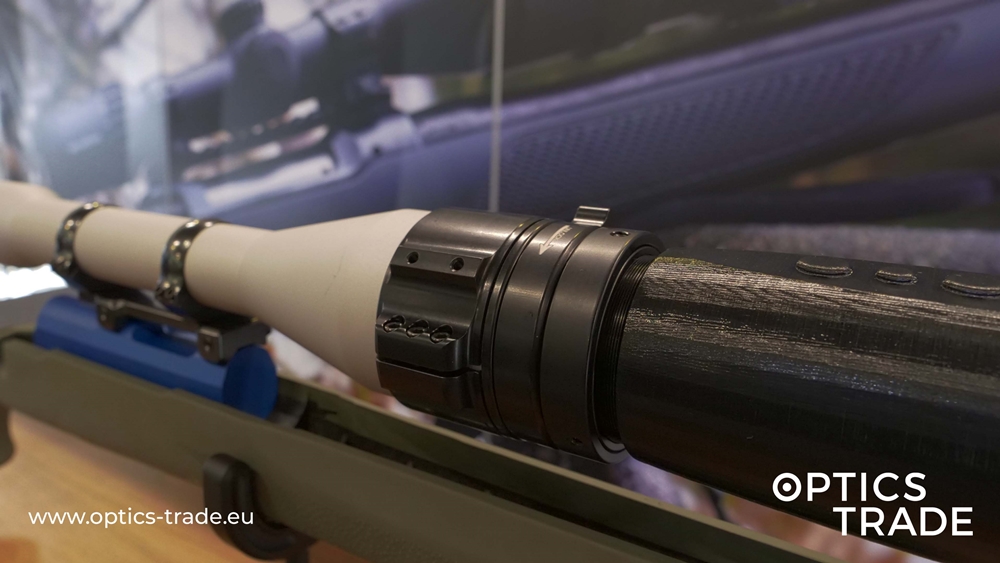

New EAW mounts are made with generative manufacturing – better known to the general public as 3D printing. This laser-based method gives the mounts their unique look. The lattice-like build is instantly recognizable, nothing like the bulky frame of traditional monoblock mounts. What is more, not only are these revolutionary mounts super-resistant to recoil, but they are also much lighter than conventional mounts. We are talking about a 30-40% percent weight drop here.

3D-printed EAW mounts are available in 2 diameters (30 and 34mm) and in 2 heights. Customers can also choose between fixed and quick-release versions. Each mount is DEVA-tested for endurance and resistance to hard recoil with 2000 shocks at 700 g-s.

Printing, Milling, Coating

This product is a true testimony to the EAW’s unmatched in-house engineering. The company worked for 2 years on this project and successfully registered the patent. The production was made possible by partnering with another German company using state-of-the-art 3D technology. Each printed batch is then transported and milled to perfection in the EAW factory. The final coating can be made in natural silver or in black anodized aluminum (for now, as additional coat/color finishes are already in the pipeline). The start to finish process of making a single batch (25 pieces) takes about 60 hours.

Made to Order Mounts

It’s no surprise then, that these mounts are not meant for mass production or stock-keeping. They are made to order and will please a meticulous customer who doesn’t believe in making any compromises. EAW priced these models between 659 and 759 EUR (VAT included). It’s a suitable figure for a such high-end mounting solution. This is also expected to be a major draw for select audiences – owning something so perfected and not easily obtainable.